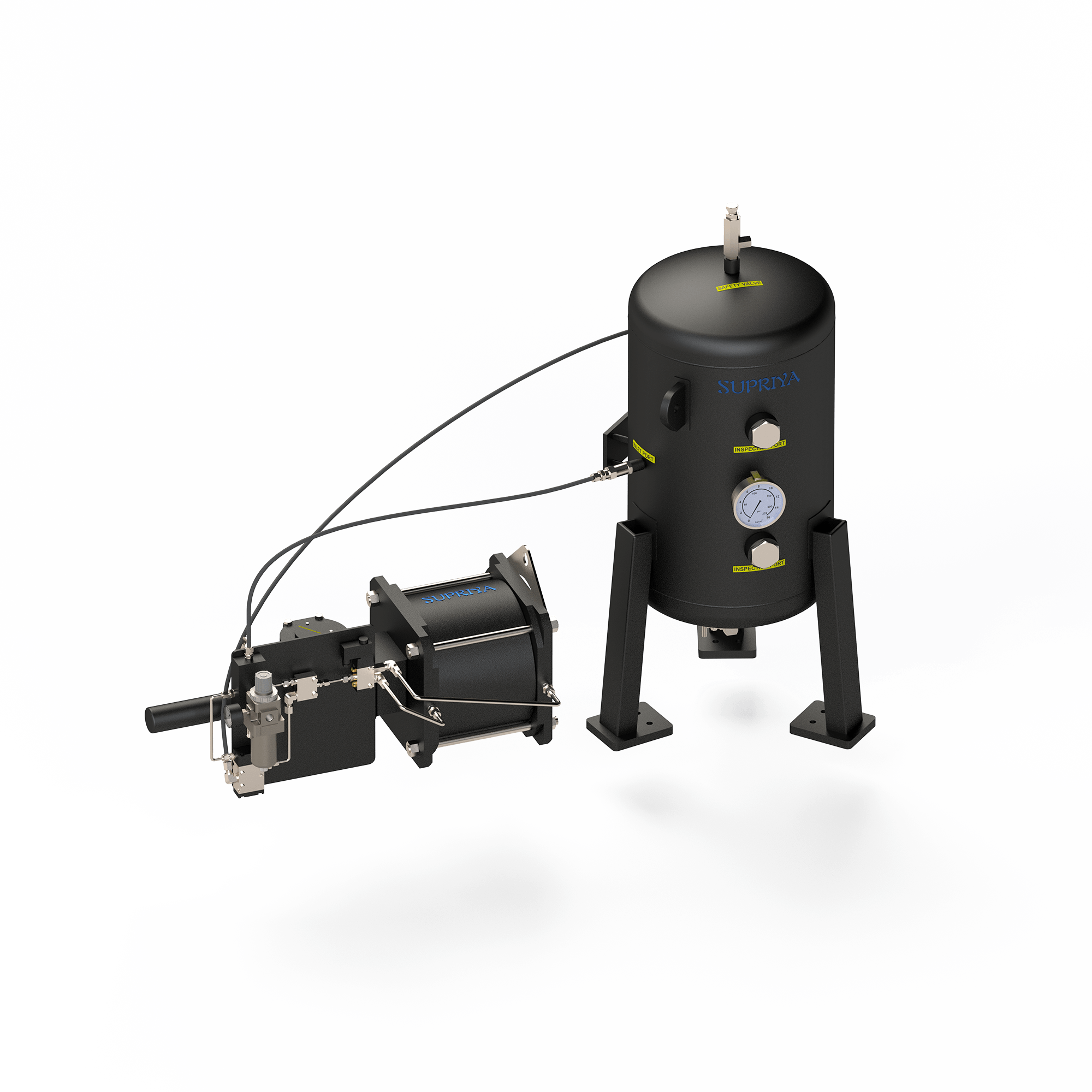

Double Acting Fail Safe Actuator (SY-DAFS)

Type – Standard

Double Acting Air Fail Safe (DAFS) System are also referred as Air-Spring Fail Safe Systems. Double Acting Pneumatic Actuator with Air Vessel / Volume Tank is connected with the customized pneumatic automation circuit to achieve Fail Safe Operation of Valve. Actuator can be configured to operate Fail Safe position as ‘Air Fail to Close’ or ‘Air Fail to Open’. The actuators operate as a double acting under regular operation whereas; source air failure drives the actuator piston in the direction of failsafe position.

Type – Boosted

Double Acting Pneumatic Cylinder, Series WC, is also available under special high pressure operating requirements. High pressure cylinder will be coupled with high pressure air vessel to operate the valve and also achieve fail safe operation. High pressure can be charged in air vessel by source air; In case source air pressure is a restriction then Pressure Booster with integrated automation circuit will be provided. For example, input supply of 5bar can be elevated to 10bar or 15bar based on requirement. Significant reduction in size of actuator, volume tank and hence its weight can be achieved through this integration. Thereby, overall highly efficient compact air actuated fail safe system can be coupled to valve.

| Type | Double Acting Fail Safe Actuator with Air Tank – Linear |

| Series | WC-DAFS |

| Type | Double Acting Scotch Yoke Actuator with Air Tank - Rotary |

| Series | SY-DAFS |

| Maximum Operating Pressure | 7bar |

| Temperature Range | minus (-)10°C to +80°C |

| Control Type | Throttling(Control Duty), On-Off Duty |