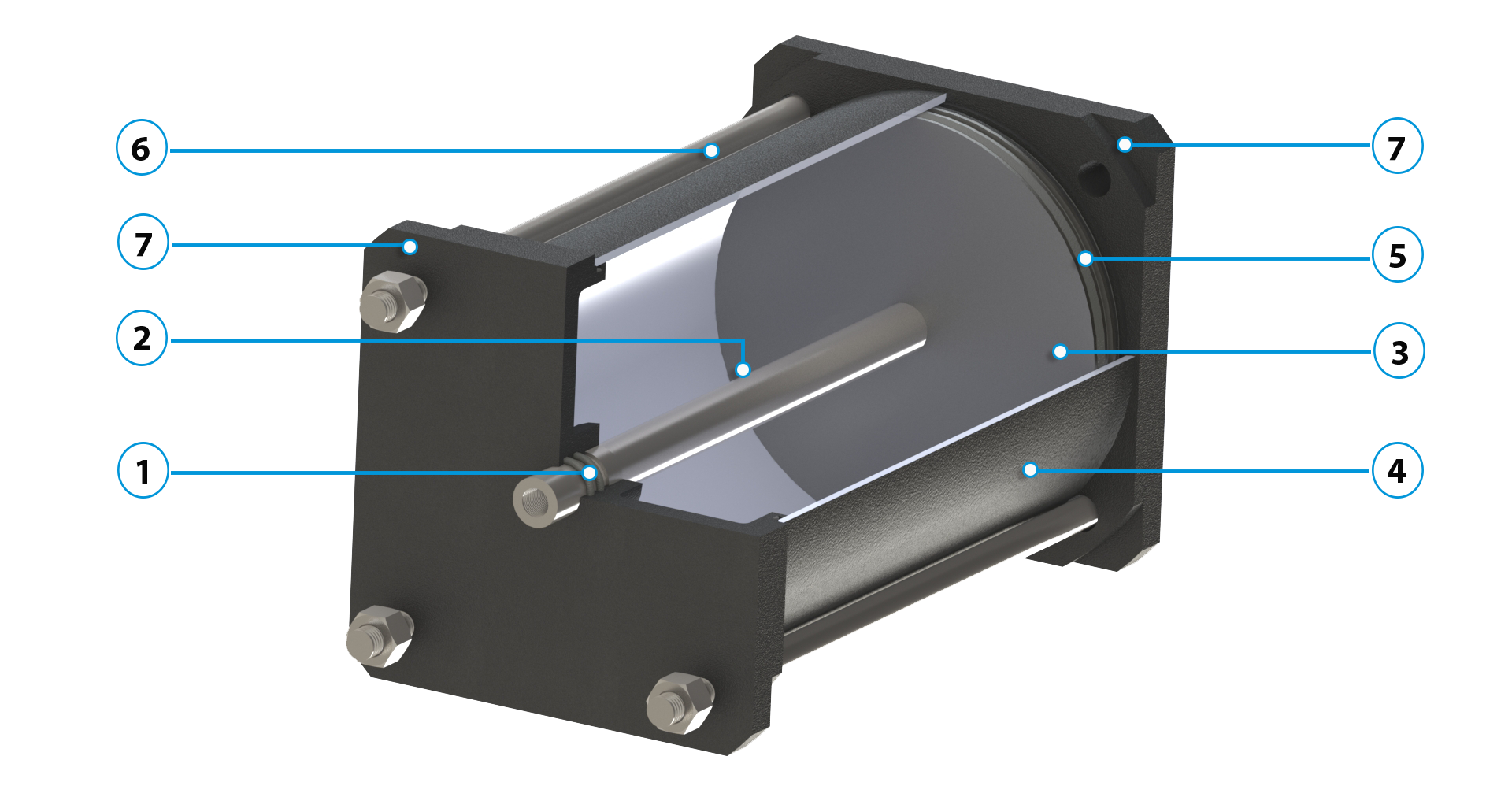

Double Acting Pneumatic Actuator (WC)

| Type | Double Acting Single Ended Linear Cylinder |

| Series | WC |

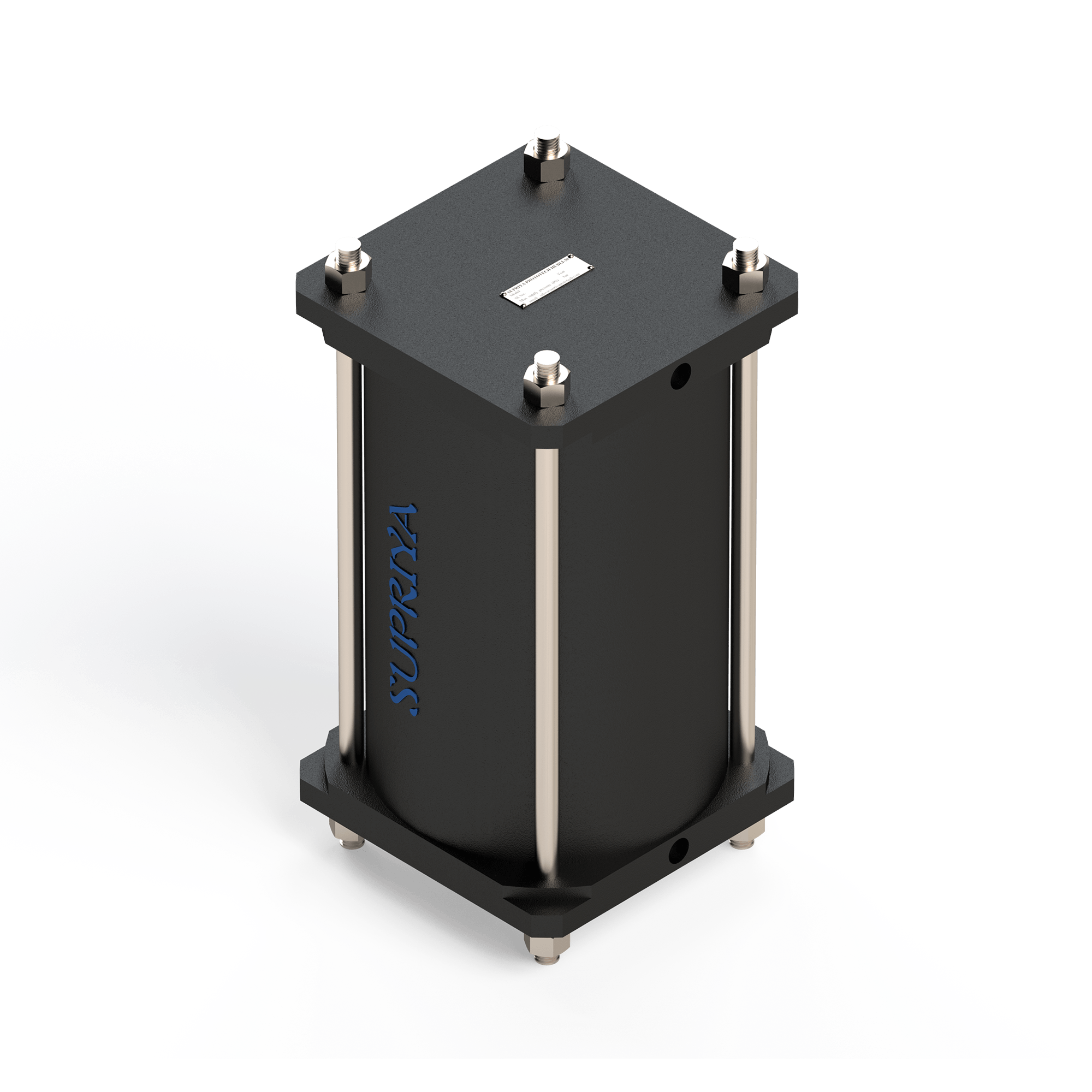

| Type | Double Acting Double Ended Linear Cylinder |

| Series | WD |

| Maximum Operating Pressure | 7bar |

| Temperature Range | minus (-) 10°C to +80°C |

| Stroke Range | up to 3000mm |

| Maximum Thrust (Single Stage) | up to 550kN |

| Maximum Thrust (Double Stage) | up to 1000kN |

| Control Type | Throttling (Control Duty), On-Off Duty |

| 1) | Performance | Supriya WC Series actuators are designed and manufactured to offer a high level of efficient and reliable performance with reduced repair requirements and increased actuator life. |

| 2) | Protection and Approval | Supriya Actuator provides protection certified to IEC IP67 as a minimum according to IEC/EN 60529 and CE certified under Pressure Equipment Directive PED 2014/68/EU. |

| 3) | Corrosion Resistance | Composite cylinder barrel, Aluminium Anodized barrel, Carbon Steel with hard chrome plated and Stainless Steel barrel for extended service life. |

| 4) | Automation | We also offer a wide range of automation options. |

| 5) | Product Life | Our actuators are designed for 20years of service life. |

| 6) | SEALS | Using standard O-rings and seals for both static and dynamic sealing makes Supriya double acting actuator soft parts lower cost and easier to find. |